Small drops speeds the production of industrial enzymes

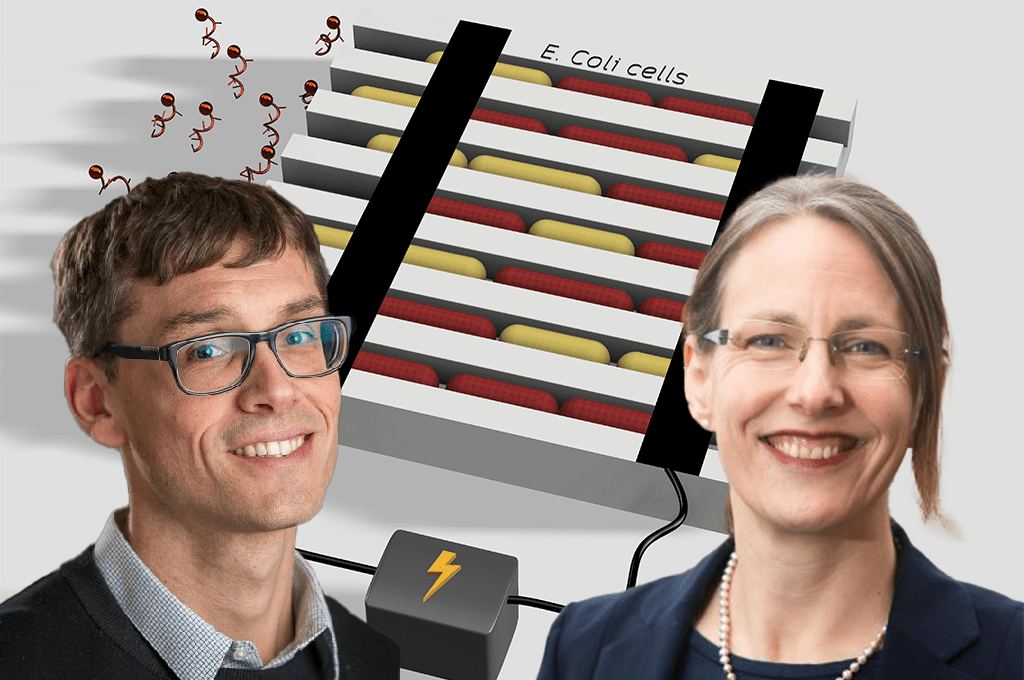

Researchers at SciLifeLab have shown that a high-throughput method using microfluidic droplet sorting of mutated yeast cells can be used to improve the production of industrial enzymes.

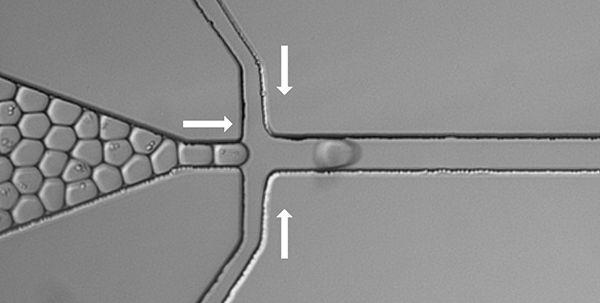

Håkan Jönsson, Scientist and Group leader at KTH Royal Institute of Technology and SciLifeLab and his colleagues have evaluated a method for analysis of individual cells and their surrounding microenvironment. Each cell is enclosed in a small droplet only 30 micrometers in diameter and with a volume of 13 picoliters surrounded by oil. The droplets are stable enough to rub up against each other without being fused (see picture above).

In an article recently published in the scientific journal Lab on a Chip, Håkan Jönsson and his colleagues from KTH and Chalmers University demonstrate how this technique can be used to select yeast cells with beneficial mutations, for example to produce large amounts of enzymes used in industry, such as amylase which is used for fermentation and in detergents. With directed evolution, the researchers expose yeast cells to ultra violet radiation to create a library of mutated cells with different properties. The next step is to identify the cells with the desired improvement, such as enhanced enzyme production. Traditionally this is done by culturing the cells on plates and picking the colonies of successfully mutated cells by hand, a difficult and time-consuming job. Using the microfluidics-technique, the mutated cells are instead isolated in separate droplets. Each droplet contains a substrate that emits fluorescent light when it is broken down by a specific enzyme produced and released by the cell into its surrounding droplet when the droplet is irradiated by laser. Cells with the “right” mutation are thus easy to detect and are automatically sorted with an electric field.

“A great advantage is that we do not have to know what genetic changes in the genome are necessary to give rise to the desired yeast strain”, says Håkan Jönsson. “With this method, we have been able to produce a yeast strain that produces 2,5 times more of the enzyme compared to the starting strain”.

The droplet microfluidics platform at SciLifeLab, which has been used in the study, has a throughput over 300 times higher than the automated microtiter plate screening system which is the current industry standard. The cost for developing efficient cell production strains is also dramatically reduced since the reagent consumption is decreased a million fold with the microfluidic system.